"BiTurbo228 - Dr Frankenstein of Spitfires" (biturbo228)

"BiTurbo228 - Dr Frankenstein of Spitfires" (biturbo228)

05/18/2016 at 05:34 ē Filed to: Spit6

2

2

40

40

"BiTurbo228 - Dr Frankenstein of Spitfires" (biturbo228)

"BiTurbo228 - Dr Frankenstein of Spitfires" (biturbo228)

05/18/2016 at 05:34 ē Filed to: Spit6 |  2 2

|  40 40 |

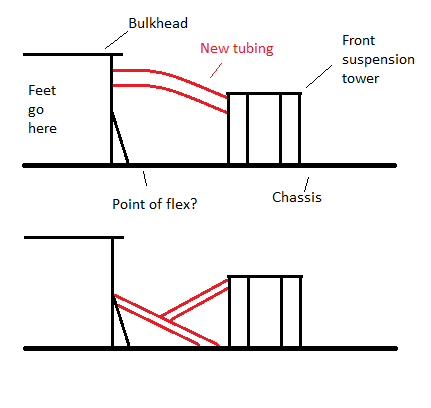

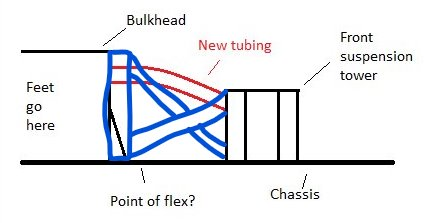

Moderns are acting up unfortunately (Alfaís needed an O2 sensor and rocker cover gaskets) but I have been stealing the odd hour here and there to make a collapsible rotisserie to mount the body onto which Iíll post up once Iíve finished. However, I have been thinking recently about chassis stiffness, specifically the area just before the bulkhead which Iím pretty sure is a major area of flex when the front suspension is compressed.

On most racecars Iíve seen they simply extend the rollcage through the bulkhead to meet the suspension towers, which Iím sure works very nicely. However, as Iím not having a full rollcage Iím fairly certain that welding/bolting a tube straight between the front towers and the bulkhead (upper drawing) would be a significant safety hazard. I can see in a front-end collision that it would either punch straight through the bulkhead or cause the bulkhead to fold/buckle in towards the driverís feet.

So, my thinking is along the lines of drawing no.2. Two tubes, one welded/bolted between the little open box that houses the chassis mount (which on mine will be boxed in) and the chassis, and then a second tube from the centre of the 1st tube and bolts onto the suspension tower.

In a front-end crash, Iíd hope that the point of weakness would be the centrepoint of the 1st tube, and it would fold there (well away from the driverís feet). I could even make the 1st tube out of thinner walled tube to ensure that thatís the part that deforms. If it works as planned, it should actually make the whole thing a bit safer as itíd essentially be and additional crumple zone :)

Ideally Iíd like to build a mockup and test it in a press, or model it in software, but I have the facilities for neither...

Ideas? Criticisms?

Also, recently met Halkyardo who was over in Blighty for a wedding. Cool chap :)

Twingo Tamer - About to descend into project car hell.

> BiTurbo228 - Dr Frankenstein of Spitfires

Twingo Tamer - About to descend into project car hell.

> BiTurbo228 - Dr Frankenstein of Spitfires

05/18/2016 at 06:02 |

|

I think youd have to make the weld between the two tubes weaker than usual so that itd break in a heavy crash otherwise it may still shunt the structure through the bulkhead. Even then the bottom tube could still puncture the bulkhead. It depends on so many factors though. Id probably consider one of those strut braces that tie the towers to the bulkhead from above as an alternative.

BiTurbo228 - Dr Frankenstein of Spitfires

> Twingo Tamer - About to descend into project car hell.

BiTurbo228 - Dr Frankenstein of Spitfires

> Twingo Tamer - About to descend into project car hell.

05/18/2016 at 06:13 |

|

The issue with the above design is that the bulkhead itself isnít particularly strong (being body on frame) so anything that uses it as a load-bearing structure is going to be compromised. Iím pretty certain that in the above design all that would happen in a crash would be either a solid metal tube being pushed straight into the cabin, or the bulkhead itself would fold down onto your legs. Not pretty.

If I made the welds weaker between the two tubes then theyíd simply shear and Iíd lose any crumpling effect to take force out of the impact. To ensure that the point of weakness is the centre of the lower bar Iíd make it out of thinner walled tube than the upper bar, meaning that it should bend in the middle. The bulkhead area where it attaches will be reinforced with a little enclosed box section, which will then be secured to the chassis.

A strut brace wouldnít work for a couple of reasons. First of is packaging (in that thereís no real way to get one of any reasonably strong design from one side to the other). Second it doesnít actually strengthen the area that flexes significantly (itíd stop the towers moving relative to each other, but as the bulkhead isnít particularly strong, especially the upper parts, itíd just flex there meaning that the front of the chassis would still flex upwards relative to the rear). Thirdly, if you tie a relatively strong tube/a-frame between the bulkhead and the suspension towers then you're going to get that punching through the bodywork and protruding into the cabin in a front-end collision.

LongbowMkII

> BiTurbo228 - Dr Frankenstein of Spitfires

LongbowMkII

> BiTurbo228 - Dr Frankenstein of Spitfires

05/18/2016 at 06:26 |

|

I'd see if there was anyone local that races them and ask for their input.

BiTurbo228 - Dr Frankenstein of Spitfires

> LongbowMkII

BiTurbo228 - Dr Frankenstein of Spitfires

> LongbowMkII

05/18/2016 at 06:34 |

|

Iíve posted on my Triumph forum so weíll see if we get any feedback from there :)

I'm fairly certain most racers run a full cage which won't have the issues with tubes protruding into the cabin in a crash. I don't want to run a cage on mine, partially because it'll be a ton more effort and partially because without a helmet I'd definitely make contact with the bars overhead which is a very nasty eventuality...

LongbowMkII

> BiTurbo228 - Dr Frankenstein of Spitfires

LongbowMkII

> BiTurbo228 - Dr Frankenstein of Spitfires

05/18/2016 at 07:03 |

|

Yeah, but they'd probably have good advice on how and where to make the crush points or maybe reinforce the bulkhead.

SidewaysOnDirt still misses Bowie

> BiTurbo228 - Dr Frankenstein of Spitfires

SidewaysOnDirt still misses Bowie

> BiTurbo228 - Dr Frankenstein of Spitfires

05/18/2016 at 07:45 |

|

I absolutely WOULD NOT attach it to the bulkhead. Seems sketchy and like all it would do is bent the body if those thick frame rails arenít holding it in place and like that will be the weak point no matter what you do. Looking at the picture below and knowing that the next crossmember connecting the frame rails is back by the rear diff, Iíd say that it could use additional cross-body bracing between the towers. Iíd start with a ďcustom fabbedĒ (ie built yourself because you can probably make a stronger one thatís uglier) strut tower brace. That will help transfer some of the cornering load to the other side of the frame and reduce the flex behind the strut tower. From there Iíd think diagonal to the of the frame welded to a mounting plate as far to the inside and back as you can without having to worry about transmission parts. That shouldnít add too much weight and wonít direct any pieces into your feet in a crash.

SidewaysOnDirt still misses Bowie

> LongbowMkII

SidewaysOnDirt still misses Bowie

> LongbowMkII

05/18/2016 at 07:48 |

|

Iíve never seen a Triumph finish a lap. Most lose wheels, have suspension parts collapse, or simply donít start :/

BiTurbo228 - Dr Frankenstein of Spitfires

> SidewaysOnDirt still misses Bowie

BiTurbo228 - Dr Frankenstein of Spitfires

> SidewaysOnDirt still misses Bowie

05/18/2016 at 08:04 |

|

If you look at a car with the engine in (GT6 for the engine Iíll be using) youíll see why a strut brace isnít really an option. Plus, it wonít actually do much to strengthen the actual point of weakness (flexing just where that first outrigger meets the main chassis rail).

Adding more outriggers wonít help either as the rest of the structure is stiffened significantly by the body (which has the outer frame rails and outriggers built into it).

The point Iíll be tying it to is that open triangular box section you can see that mounts to the chassis with a bolt at the bottom. That will likely be rebuilt with 3mm plate and fully enclosed to increase strength. The load transferred in both a crash and normal driving will be transferred down the longest section of that triangle, meaning that it will be much more likely to stay solid than the thinner walled lower tube which should bend in the centre where the force is concentrated from the upper tube.

You can tell a Finn but you can't tell him much

> BiTurbo228 - Dr Frankenstein of Spitfires

You can tell a Finn but you can't tell him much

> BiTurbo228 - Dr Frankenstein of Spitfires

05/18/2016 at 08:14 |

|

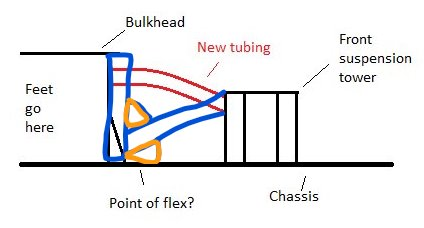

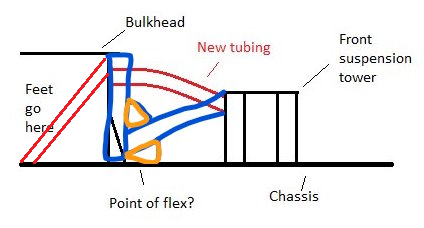

How about if you put a reinforcing tube vertically on the bulkhead, then a brace tube to the top of the suspension tower with gussets between the tubes and between the tube and chassis?

BiTurbo228 - Dr Frankenstein of Spitfires

> You can tell a Finn but you can't tell him much

BiTurbo228 - Dr Frankenstein of Spitfires

> You can tell a Finn but you can't tell him much

05/18/2016 at 08:38 |

|

That would certainly be the strongest possible structure.

The issue there is that for an otherwise unmodified car that would move the point of weakness to the bulkhead itself, probably trying to fold it backwards at its base towards your feet. In an ideal world Iíd put one more brace in tying the top of the reinforcement tube back down to the chassis, but space around your feet is already so tight on these cars that itíd be all but impossible.

With my design I've build in a deliberate area of weakness (tying the upper tube to the centrepoint of the lower tube) a good distance before any inhabited areas of the car. That way it should still provide added stiffness, but in a crash it should fold around that area of weakness and not one that's got you in it!

SidewaysOnDirt still misses Bowie

> BiTurbo228 - Dr Frankenstein of Spitfires

SidewaysOnDirt still misses Bowie

> BiTurbo228 - Dr Frankenstein of Spitfires

05/18/2016 at 08:52 |

|

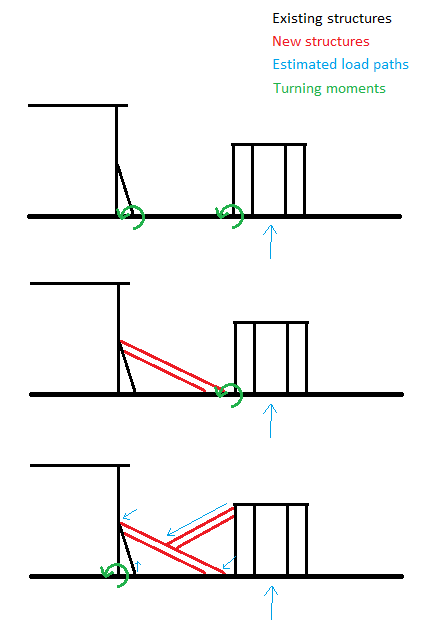

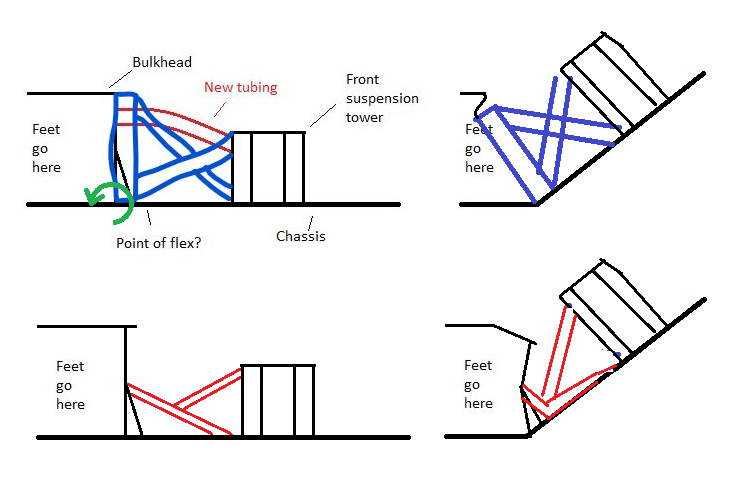

I had a great post written before kinja ate it. Iíll just share the pic so youíll see that I mean. It will fit because itís similar to your current designs, just simpler. Iím moving the energy to a different spot. I see the frame flexing two ways. Itís bending at the front of the outrigger, but itís also twisting inward. Iím trying to redirect that downwards onto a stronger part of the rail where the outrigger meets the rail instead of forwards of it. This will move some downward force behind the flex point and act as a brace against the twisting action being caused by the height of the strut tower.

SidewaysOnDirt still misses Bowie

> BiTurbo228 - Dr Frankenstein of Spitfires

SidewaysOnDirt still misses Bowie

> BiTurbo228 - Dr Frankenstein of Spitfires

05/18/2016 at 08:55 |

|

Pictures eaten by kinja.... Ugh.

BiTurbo228 - Dr Frankenstein of Spitfires

> SidewaysOnDirt still misses Bowie

BiTurbo228 - Dr Frankenstein of Spitfires

> SidewaysOnDirt still misses Bowie

05/18/2016 at 08:57 |

|

Well kinjaís playing nice today...

You can tell a Finn but you can't tell him much

> BiTurbo228 - Dr Frankenstein of Spitfires

You can tell a Finn but you can't tell him much

> BiTurbo228 - Dr Frankenstein of Spitfires

05/18/2016 at 08:59 |

|

Instead of bringing your bracing back from the top of the added bulkhead tube you could bring it forward. The extra bracing wouldnít be in the way of your feet and it would actually make everything stiffer. This does add the complexity of intersecting tubing though and makes for more difficult welding. It would be by far the stiffest option, but it is adding weight to the front of the car.

RamblinRover Luxury-Yacht

> BiTurbo228 - Dr Frankenstein of Spitfires

RamblinRover Luxury-Yacht

> BiTurbo228 - Dr Frankenstein of Spitfires

05/18/2016 at 09:19 |

|

Iíve just been working on rear frame stiffeners and such on my project, so this is relevant to my interests. As to fear of attaching things straight to the bulkhead, I think thatís largely what they did on the Jag E, so I wouldnít be that worried. At any rate, Iíd be tempted not to use tube, but to use <1/8" folded channel - say 2.5mm 1" tall x 2" wide - open up, positioned much like the tube in the top picture. A little more ďsquaringĒ strength, and under failure, doesnít shoot a pointed weld-fractured bit of tube into the cabin, but itself spreads open and folds upward. Stiff, but has a defined mode of buckling.

SidewaysOnDirt still misses Bowie

> BiTurbo228 - Dr Frankenstein of Spitfires

SidewaysOnDirt still misses Bowie

> BiTurbo228 - Dr Frankenstein of Spitfires

05/18/2016 at 09:19 |

|

Letís try this again....

BiTurbo228 - Dr Frankenstein of Spitfires

> You can tell a Finn but you can't tell him much

BiTurbo228 - Dr Frankenstein of Spitfires

> You can tell a Finn but you can't tell him much

05/18/2016 at 09:20 |

|

That would definitely be the stiffest option, but again the weak point would be the bulkhead where my feet need to live. Hereís a (rough) sketch of what I reckon would happen in a front-end collision:

With a proper cage to back it up yours would be by far the safer option, but I canít do that here. Partially due to space constraints around my feet, partially itís tons more work and most importantly my unhelmeted head will contact the roof bars in a crash which is very, very bad.

SidewaysOnDirt still misses Bowie

> SidewaysOnDirt still misses Bowie

SidewaysOnDirt still misses Bowie

> SidewaysOnDirt still misses Bowie

05/18/2016 at 09:21 |

|

Ugh, nope.

BiTurbo228 - Dr Frankenstein of Spitfires

> SidewaysOnDirt still misses Bowie

BiTurbo228 - Dr Frankenstein of Spitfires

> SidewaysOnDirt still misses Bowie

05/18/2016 at 09:22 |

|

Did you try doing the rain dance and sacrificing a virgin goat this time? Thatís the usual procedure to get it working again...

I really want to see this design as well. Sounds interesting...

SidewaysOnDirt still misses Bowie

> BiTurbo228 - Dr Frankenstein of Spitfires

SidewaysOnDirt still misses Bowie

> BiTurbo228 - Dr Frankenstein of Spitfires

05/18/2016 at 09:27 |

|

Links?

https://imageshack.com/i/pow3vWo5j

https://imageshack.com/i/pnryfc0Hj

BiTurbo228 - Dr Frankenstein of Spitfires

> RamblinRover Luxury-Yacht

BiTurbo228 - Dr Frankenstein of Spitfires

> RamblinRover Luxury-Yacht

05/18/2016 at 09:29 |

|

The thing Iím thinking regarding the Jag bulkhead is that they had some pretty clever engineers (involved in the C and D-type racers most likely) that were designing a semi-monocoque car from scratch. Me, Iím cobbling together a semi-monocoque car from a mostly body-on-frame car based primarily on intuition :S

I like the idea of using channel with a specific area of failure. I'll look into that :)

BiTurbo228 - Dr Frankenstein of Spitfires

> SidewaysOnDirt still misses Bowie

BiTurbo228 - Dr Frankenstein of Spitfires

> SidewaysOnDirt still misses Bowie

05/18/2016 at 09:34 |

|

Aha, gotcha. That would work as it'd transfer the load to a stronger part of the existing chassis. Not quite as strong, but safer and lighter too :)

BiTurbo228 - Dr Frankenstein of Spitfires

> SidewaysOnDirt still misses Bowie

BiTurbo228 - Dr Frankenstein of Spitfires

> SidewaysOnDirt still misses Bowie

05/18/2016 at 09:34 |

|

The more I think about that, the more of a clever solution it proves to be. I'm impressed :)

RamblinRover Luxury-Yacht

> BiTurbo228 - Dr Frankenstein of Spitfires

RamblinRover Luxury-Yacht

> BiTurbo228 - Dr Frankenstein of Spitfires

05/18/2016 at 09:42 |

|

The way I see it is, it only has to be heavy enough and strong enough to hold things stiff in normal driving and soak a bit of energy in a prang. Anything past that is gravy. As such, building a dedicated energy absorber thatís much beyond just a *dash* of stiffening runs risks of weight and unintended consequences - simply put, you may want to take the Lotus approach and use the weakest possible piece that will do the job.

SidewaysOnDirt still misses Bowie

> BiTurbo228 - Dr Frankenstein of Spitfires

SidewaysOnDirt still misses Bowie

> BiTurbo228 - Dr Frankenstein of Spitfires

05/18/2016 at 09:43 |

|

I still think that a strut tower would do alot for the inward torque thatís doing the twisting and reducing the stiffness of the square frame. Iíd do it in two pieces and Iíd make them thin so as to avoid making them stronger than their mounts, but Iíd run a V style one like you see in the BRZ engine bay where you have them bolted from the tower to the firewall. Being in the center behind the dash, Iíd be less worried about it coming through, but I think it can be spread sufficiently with a backing plate for the weak points to either be the strength of the bars or if you flatten and cut the tower side and weld that to a backing plate, I imagine that weld would snap under an impact because the strength of the tube would be compromised and more likely to twist there.

BiTurbo228 - Dr Frankenstein of Spitfires

> RamblinRover Luxury-Yacht

BiTurbo228 - Dr Frankenstein of Spitfires

> RamblinRover Luxury-Yacht

05/18/2016 at 10:00 |

|

Gotcha, so if I do go for tubing (as Iíve got lots of that) I might reduce the wall thickness to 2mm for the upper tube and 1.5mm for the lower. Should still be stiff, but even less likelihood of breaking something further up the line.

The advice is sound, but quoting Clarke-era Lotus to support a safety argument doesnít sound like a supporting argument ;)

BiTurbo228 - Dr Frankenstein of Spitfires

> SidewaysOnDirt still misses Bowie

BiTurbo228 - Dr Frankenstein of Spitfires

> SidewaysOnDirt still misses Bowie

05/18/2016 at 10:04 |

|

I suppose in the centre of the bulkhead would move it away from the occupants, but the dash is the flimsiest thing on the car so I doubt that would do anything other than bend into pointy bits to stab you with in a crash.

A v brace would probably do quite a lot stiffness-wise, but packaging that would be a nightmare. It'd have to pass through areas occupied by the exhaust manifold, inlet manifold, throttle linkages and steering column. Damn reverse-flow heads and tiny little cars...

RamblinRover Luxury-Yacht

> BiTurbo228 - Dr Frankenstein of Spitfires

RamblinRover Luxury-Yacht

> BiTurbo228 - Dr Frankenstein of Spitfires

05/18/2016 at 10:16 |

|

HA. Well, I think we can be agreed that ďIf a component survives the race, itís too strongĒ is taking things a bit far, but as youíre already blasting about in a cardboard box, making sure same cardboard box doesnít have any massive structure is prudent enough. Then again, Iím building a whole semi-cage for the Ranchero with up to .187 wall tubing so what do I know...

SidewaysOnDirt still misses Bowie

> BiTurbo228 - Dr Frankenstein of Spitfires

SidewaysOnDirt still misses Bowie

> BiTurbo228 - Dr Frankenstein of Spitfires

05/18/2016 at 10:20 |

|

Yeah, I was expecting the bulkhead to be practically useless there, which is why I was suggesting heavy reinforcement. Packaging would be a bitch,so hereís another idea. Turning the enging into a stressed component. ;) Bolt a bar from strut tower to engine.

BiTurbo228 - Dr Frankenstein of Spitfires

> RamblinRover Luxury-Yacht

BiTurbo228 - Dr Frankenstein of Spitfires

> RamblinRover Luxury-Yacht

05/18/2016 at 10:27 |

|

Nice :) I thought about incorporating a roll hoop into the structure of the hardtop, but itíd be a lot of work and Iíd quite like to drive the damn thing sometime soon :)

Any progress on the Ranchero recently?

BiTurbo228 - Dr Frankenstein of Spitfires

> SidewaysOnDirt still misses Bowie

BiTurbo228 - Dr Frankenstein of Spitfires

> SidewaysOnDirt still misses Bowie

05/18/2016 at 10:32 |

|

Yeah I thought that solid-mounting the engine would do a great job of adding stiffness without adding weight, but my mate has a 106 GTi racecar with a solid-mounted engine. The previous owners had to do a complete bolt-check prior to each race to ensure they hadnít shaken loose, and my mate is in the process of wire-locking every damn bolt on the car. Neither are things Iíd like to do :S

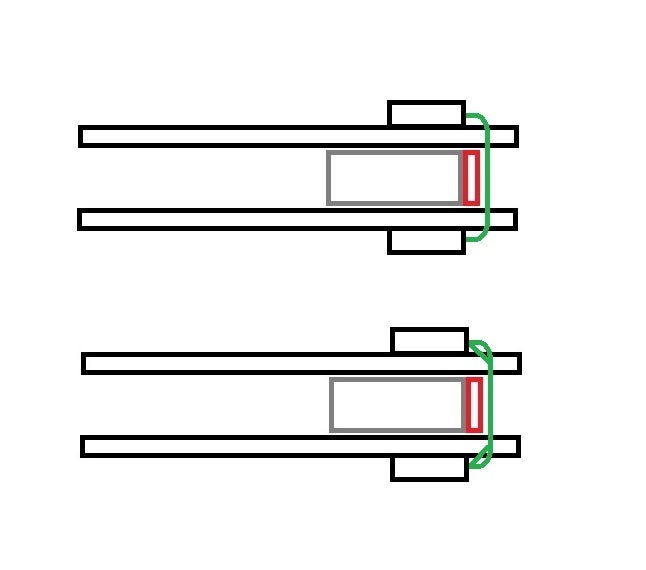

Another option mentioned on my Triumph forum is running a strut brace in front of the engine. The pic below is as viewed from above. Light grey is engine, red is ancilliaries and the boxes either side of the main rails are the suspension towers. The green strut brace might just be able to sneak in front of the ancilliaries but behind the radiator, although I'd need a mockup to check for clearance...

SidewaysOnDirt still misses Bowie

> BiTurbo228 - Dr Frankenstein of Spitfires

SidewaysOnDirt still misses Bowie

> BiTurbo228 - Dr Frankenstein of Spitfires

05/18/2016 at 10:39 |

|

Yeah, that would work.

RamblinRover Luxury-Yacht

> BiTurbo228 - Dr Frankenstein of Spitfires

RamblinRover Luxury-Yacht

> BiTurbo228 - Dr Frankenstein of Spitfires

05/18/2016 at 10:43 |

|

Actually, not too little. I took three days off last week to try to catch up on some of that. Iíve made one of the remaining fills for the floor, welded up some bits on the back lip where I was reshaping the rear body to match the bumper, fixed a golf ball-sized dent and a crease in the back corner a previous nitwit had filled with Bondo, changed the under-bed crossmembers to support the fuel tank differently, and moved the fill on the fuel tank (as itís a sedan fuel tank Iím filling differently than the station wagon stock). I welded over the original fill location on the outside of the fender, cut some pieces for supporting the front bed plate (covers the rear ďfloorboardsĒ, closes the bed to the cab), acid-treated the plate, and Iíve mocked up how the ďmidgateĒ - the folding down back part of the cab - will fold, as well as doing some trimming on it. Iíve also shortened both doors to fit with the 7" raised sills, welded two splash guard sort of fender bracing plates in place after modifying them, and I finally last night came up with the details of how the rear roll hoop will attach to the body.

Monday, of course, was something different - did a swap of all eight secondary suspension links in back of the Mercedes after work. The creak on the left and the wheel hop on the right are both gone, at the expense of $140 in parts and about 3.5 hours on the lift.

BiTurbo228 - Dr Frankenstein of Spitfires

> RamblinRover Luxury-Yacht

BiTurbo228 - Dr Frankenstein of Spitfires

> RamblinRover Luxury-Yacht

05/18/2016 at 10:51 |

|

Nice :) I need a couple of days off to catch up too as itís beginning to mount up. On the to-do list is replace the rocker cover gaskets on the Alfa, realign the subframe and change the steering arms. The Citroenís developed a hydraulic leak on a return pipe that needs sorting. The MG Fís approaching timing belt time and the Jag needs the CWP aligning properly as I didnít get it right the first time and Iím fairly certain itís chewing itself to pieces...

But nah, Spitfire's more fun ;)

RamblinRover Luxury-Yacht

> BiTurbo228 - Dr Frankenstein of Spitfires

RamblinRover Luxury-Yacht

> BiTurbo228 - Dr Frankenstein of Spitfires

05/18/2016 at 11:24 |

|

I mentioned your existence in a conversation here at work regarding UK airports, and that you had an MGB slated for shenanigans, an Alfa, a Citroen, and a Spit undergoing surgery - the response was ďI see why heís your friendĒ. Not sure it was a compliment, to be honest :D

BiTurbo228 - Dr Frankenstein of Spitfires

> RamblinRover Luxury-Yacht

BiTurbo228 - Dr Frankenstein of Spitfires

> RamblinRover Luxury-Yacht

05/18/2016 at 11:29 |

|

Hah :) sounds about right ;)

RamblinRover Luxury-Yacht

> BiTurbo228 - Dr Frankenstein of Spitfires

RamblinRover Luxury-Yacht

> BiTurbo228 - Dr Frankenstein of Spitfires

05/18/2016 at 11:59 |

|

At any rate, Iím trying to fast-track all the remaining heavy frame/thick walled things for welding so I can finish them up and step down to .023 wire for undergoing massive patching. The .030 is a bit infuriating to try to do up corroded 22GA panels with, if Iím honest.

Twingo Tamer - About to descend into project car hell.

> BiTurbo228 - Dr Frankenstein of Spitfires

Twingo Tamer - About to descend into project car hell.

> BiTurbo228 - Dr Frankenstein of Spitfires

05/19/2016 at 08:02 |

|

All valid points, I personally would also put a bend in the middle of the pipe as well to fully ensure it deforms properly. But you obviously know your car a hell of a lot better than I do so I think you have a strong grasp of what you're doing. Keep us clued in on the progress im interested to see how it goes.

BiTurbo228 - Dr Frankenstein of Spitfires

> Twingo Tamer - About to descend into project car hell.

BiTurbo228 - Dr Frankenstein of Spitfires

> Twingo Tamer - About to descend into project car hell.

05/19/2016 at 08:16 |

|

The bend in the pipe is a great idea. Gives it even more of a pre-determined failure point while still keeping it stiff. Plus it would reduce the chances of the weakest point being the welds holding the upper tube to the lower one, which might cause them to fracture.

Twingo Tamer - About to descend into project car hell.

> BiTurbo228 - Dr Frankenstein of Spitfires

Twingo Tamer - About to descend into project car hell.

> BiTurbo228 - Dr Frankenstein of Spitfires

05/19/2016 at 13:17 |

|

Yeah I think it could work out pretty well.